Updates

Products

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

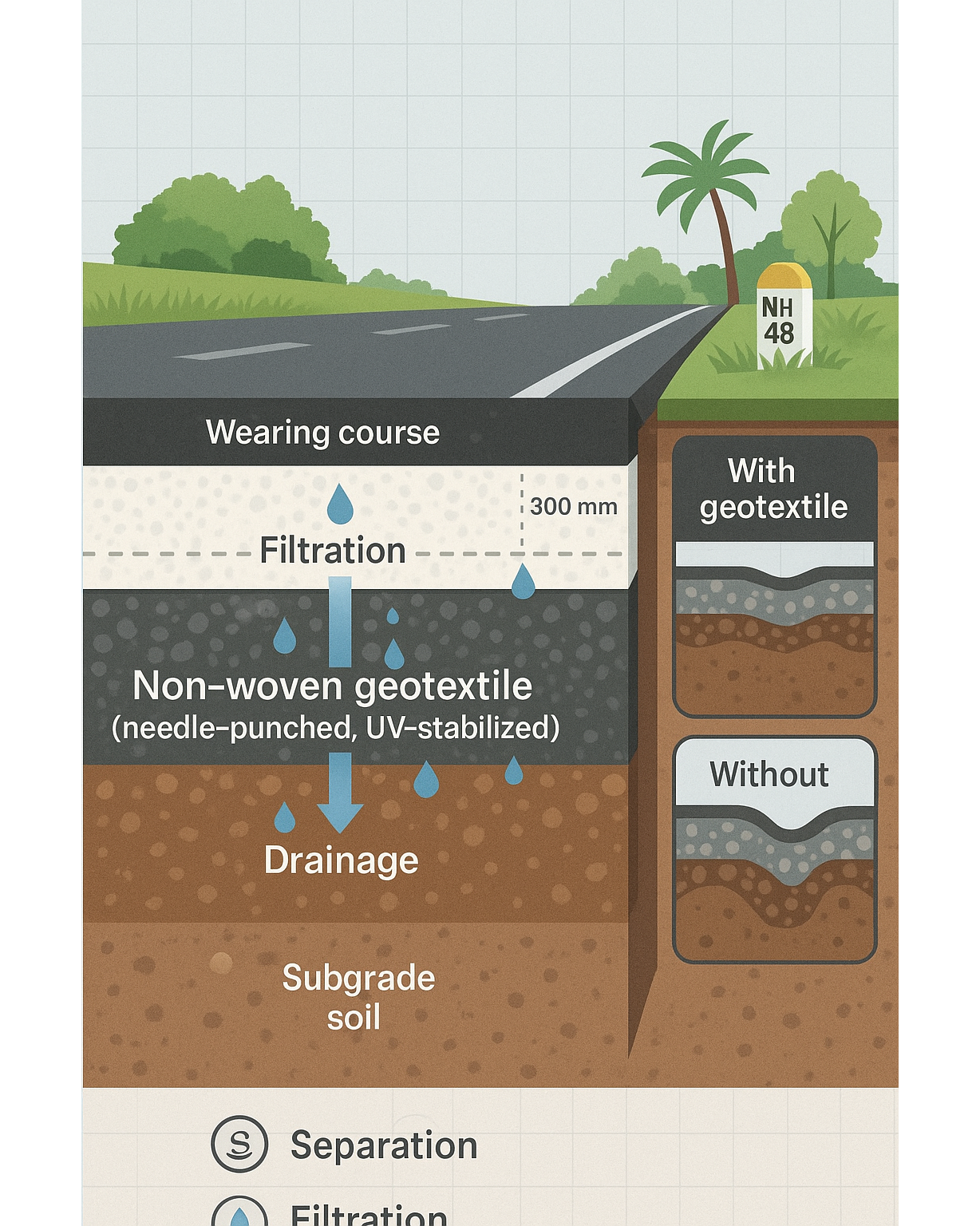

A site engineer on the Pune ring road told me a quiet truth: “The asphalt wasn’t failing. The soil was.” Trucks queued, ruts deepened, we kept resurfacing—and the problem kept bubbling up from below. The fix wasn’t louder machinery; it was a silent fabric. Non-woven geotextile. Here’s the simple power of this humble layer—separate, filter, drain. When we keep subgrade fines from pumping into aggregates, allow water to pass without soil migration, and move that water out quickly, pavements live longer and shoulders stop unraveling. We save capex, cut maintenance closures, and reduce crash risk from sudden edge breaks. That’s not glamour; that’s good engineering. Look around India and you’ll see where it matters most: black cotton soils in Vidarbha, reclaimed stretches along Mumbai’s coast, peri-urban service roads around Delhi, and hill corridors in the Northeast where every monsoon tests our resolve. Projects that specify needle-punched, UV-stabilized non-woven geotextiles under carriageways, side-drains, and medians are quietly winning the long game. What should we do differently? 📌 Design: Classify soils honestly. Decide where separation vs. filtration is non-negotiable—under base, at drains, behind retaining structures. 📌 Procurement: Insist on tested properties—mass per unit area, grab tensile, CBR puncture, permittivity, and characteristic opening size. Don’t buy by GSM alone. 📌 Execution: Maintain overlaps, protect during placement, avoid wrinkles, place aggregates without tearing, and document with photo logs. 📌 Audit: Random sample rolls on-site, verify mill certificates, and record near-misses like shoulder settlement or drain clogging; fix top 3 causes monthly. Policy nudge: Let’s embed geotextile checkpoints into DPR reviews and BoQ templates, and make site audits for sub-surface layers as routine as cube tests. MoRTH/IRC already give the playbook—our job is to apply it with discipline. Safer roads are a shared responsibility. 💡 I’ll drop a simple visual in comments: “with vs. without separation” showing fines migration and drainage paths. This month, audit two active packages for geotextile use at shoulders and side-drains, retrofit where missing, and publish a one-page remediation plan. If you run fleets, pilot geotextiles in your depot yards to stop rutting and slips after rain. Progress starts under our feet—literally. @NHAI @Civil Engineering Expert @CSR Partner #RoadSafety #Infrastructure #NHAI #MoRTH #IRC #Highways #Geotextiles #Pavements #CivilEngineering #India #Sustainability #CSR