Updates

Products

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

A single bright line can save a life. Across our cities, faded markings turn lanes into guesswork—especially after the monsoon. Thermoplastic is different: heat-applied with glass beads that return light to drivers, it stays visible at night and in rain, guiding speed and decisions. Recent makeover near a Thane school: fresh zebra, bold “SLOW SCHOOL, ” and stop lines—machine-laid and inspected at night. Noise dropped, drivers complied, kids crossed with confidence. Basics done right. 📌 What we deliver • Machine-laid thermoplastic to IRC:35 / MoRTH 803 • Night audits with retroreflectivity checks • Proper arrows, chevrons, and edge lines for arterials/expressways • Maintenance cycles pre- & post-monsoon 💡 Quick wins you can start this month ✅ Night audit on 10 km of corridor; publish fixes ✅ Retrofit fleets with seatbelt alarms beyond 1 minute ✅ Adopt 2 school zones—crossings, advance warnings, legends ✅ Quarterly driver training + spot checks Safer roads are a shared responsibility. If you manage projects, CSR or fleets—let’s get your lines shining again. @Ministry of Road Transport @Industry Leader @CSR Partner #RoadSafety #Thermoplastic #RoadMarkings #NHAI #MoRTH #UrbanMobility #Highways #SchoolZones #FleetSafety #CSR #India

A rainy evening in Indore. Fresh thermoplastic zebras and a “SLOW SCHOOL” roundel turn chaos into choreography. Buses brake earlier, two-wheelers hold their lines, a child crosses without running. The “boring” lines are saving lives. Thermoplastic isn’t just paint—it’s hot-applied, bead-rich, and built to shine through monsoon nights. When we pair it with audits, calming, and enforcement, crash risk drops fast. Let’s make this our default in school zones, slip roads, toll plazas, and curves. 📌 Next 90 days: ✅ Audit 50 km per district for missing/faded markings; fix top 3 issues per stretch. ✅ Adopt 2 school zones—zebras, advance bars, “SLOW SCHOOL”, signage. ✅ Monthly near-miss logs from fleets/dashcams; repaint where conflict repeats. ✅ Quarterly crew training on bead rate, thickness, and night checks. Safer roads are a shared responsibility. Share this with your teams, contractors, and local traffic cells. ♻ —Hitesh Lunia | The Reformist Storyteller Tag partners who can move fast: @MoRTH_Official @NHAI_Official @CityTrafficPolice @CSIRCRRI @SaveLIFEFoundation @WRIIndia @3MIndia @MahindraLogistics @TataMotors @LarsenToubro

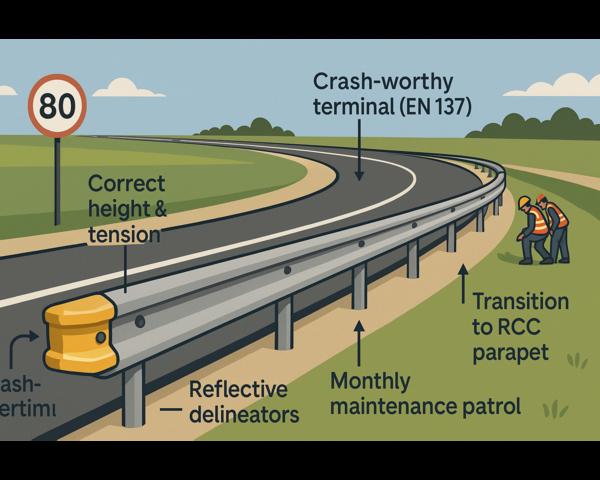

We don’t have a shortage of “tech.” We have a shortage of outcomes. India lost **1, 72, 890 people in 2023** to road crashes—each one a name, a family, a future. Enforcement cameras alone won’t bend that curve. On Delhi–Gurgaon and Dwarka expressways, ANPR issued thousands of challans, yet fatalities still climbed. The lesson is simple: **products must be part of a system**, not a photo-op. 🚧 Here’s what works when we connect the dots between hardware, habit, and highway design: 📌 **Seatbelt systems that don’t give up.** Most cars let alarms go quiet after a minute. That’s not safety; that’s theatre. Extend alarms beyond the first minute, pair with **visible rear-belt indicators**, and watch compliance rise. Fleet owners in Gurgaon who hard-locked reminders reported fewer “I’ll wear it later” excuses during night runs. 📌 **Barrier integrity, not barrier cosmetics.** A W-beam is only as good as its **end terminals, spacing, and maintenance**. Recent NHAI circulars have tightened the screws on installation quality—good. Now EPCs must audit active packages for missing terminals and impact attenuators, especially on curves and medians. The Mumbai–Pune corridor’s before-after fixes proved this: fewer crossovers, fewer tragedies. 📌 **Speed control that’s physical, not just digital.** Speed cameras deter, but **traffic calming** slows—every time. In school zones across Pune and Bengaluru, raised crossings + gateway signage + compact roundabouts cut risky speeds to under **25 km/h**. Pair that with **monthly near-miss reporting** from marshals, and you get prevention, not post-mortems. 📌 **Driver training with teeth.** Quarterly refreshers sound great; **spot checks** make them real. If your fleet telemetry flags harsh braking at 2 a.m. on the Outer Ring Road, pull that driver for a 30-minute micro-coaching the next day. Behavior changes when feedback is immediate. 💡 Solutions menu you can deploy this quarter: ✅ Seatbelt alarms beyond the first minute; retrofit fleets ✅ Monthly near-miss reports; fix the top 3 causes, every month ✅ Adopt 2 school zones for calming + signage package ✅ Quarterly driver training with random spot checks Progress is pragmatic. Tragedies are preventable. *Safer roads are a shared responsibility.* Tagging leadership to align policy, engineering, and CSR: @Ministry of Road Transport @NHAI @Industry Leader @CSR Partner **CTA:** Share this with your safety team today. Pick **two products** from the list, budget them in this quarter, and publish your before–after metrics in 90 days. #RoadSafety #NHAI #Highways #CrashBarriers #SeatBelts #SchoolZones #FleetSafety #CSR #Enforcement #TrafficCalming #India #VisionZero

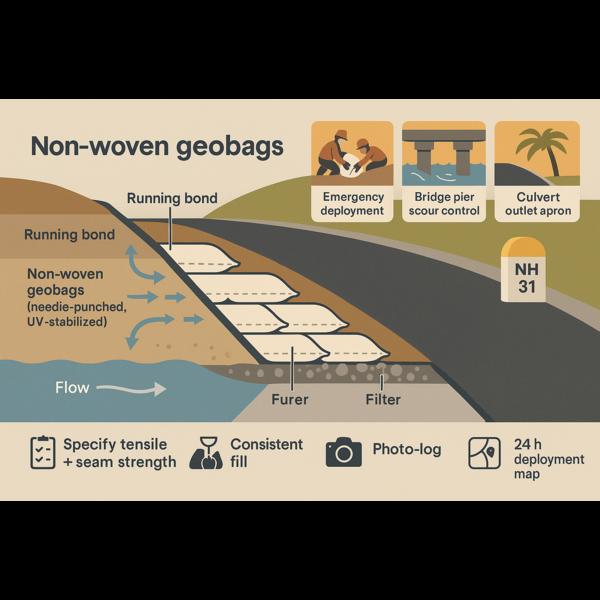

A flood-night in Samastipur, Bihar. Villagers stacked white fabric bags by torchlight. By dawn the river still roared—yet the bank held. The heroes weren’t concrete or cranes. Non-woven geo bags did the quiet, clever work. Why do they work so well? Flexibility, filtration, and speed. Fill with local sand, stitch strong seams, and you’ve built armour that bends with currents, lets water pass, and traps fines. When minutes matter, this is resilience you can carry in a pickup. Picture three scenes across India. Konkan coast—storm surge chews a beach; geo bags buy the village a monsoon. Brahmaputra belt—pier scour threatens a bridge; bags calm the toe before the next crest. Pune peri-urban—culvert outlet erodes after every shower; a small apron of bags stops the rutting and the repair circus. Three places, one tool. 📌 Procurement discipline ♻ Don’t buy by GSM alone. Demand needle-punched non-woven, UV stability, puncture resistance, tensile + seam strength, and an opening size that filters without piping. Insist on mill certificates and on-site sampling. Cheap is costly when seams burst. 🚧 Execution that lasts Prepare the bed. Run a staggered (running bond) pattern. Maintain consistent fill. Anchor the toe. Photo-log every reach, mark flood lines, and do a walk-back after first high flow. Repair. Relay. Learn. Policy nudge Embed geo-bag options in DPRs for river-adjacent highways and bridge approaches; align with MoRTH/IRC geosynthetics guidance; include a 24-hour geo-bag deployment plan in monsoon SOPs. We audit concrete cubes—why not our sandbags? 💡 Action menu—start this week ✅ Pre-monsoon audit of two erosion hot spots within 10 km of your site. ✅ Train a 15-member local crew on filling, seams, anchoring, and safety. ✅ Maintain a rapid-response inventory (fabric, thread, needles, tags) and update counts monthly. ✅ Share a one-page “after-flood inspection” with photos; fix the top three learnings next cycle. We can save banks, bridges, and budgets—without waiting for perfect walls or perfect weather. Progress is practical. Safer roads are a shared responsibility. Adopt a vulnerable stretch, run a weekend mock drill, and post your before-after to your site team. Your ripple can become policy. @Ministry of Road Transport @Industry Leader @CSR Partner #Geobags #Geotextiles #MonsoonPrep #ErosionControl #RiverTraining #BridgeSafety #RoadSafety #Highways #NHAI #MoRTH #Infrastructure #DisasterResilience #India

A site engineer on the Pune ring road told me a quiet truth: “The asphalt wasn’t failing. The soil was.” Trucks queued, ruts deepened, we kept resurfacing—and the problem kept bubbling up from below. The fix wasn’t louder machinery; it was a silent fabric. Non-woven geotextile. Here’s the simple power of this humble layer—separate, filter, drain. When we keep subgrade fines from pumping into aggregates, allow water to pass without soil migration, and move that water out quickly, pavements live longer and shoulders stop unraveling. We save capex, cut maintenance closures, and reduce crash risk from sudden edge breaks. That’s not glamour; that’s good engineering. Look around India and you’ll see where it matters most: black cotton soils in Vidarbha, reclaimed stretches along Mumbai’s coast, peri-urban service roads around Delhi, and hill corridors in the Northeast where every monsoon tests our resolve. Projects that specify needle-punched, UV-stabilized non-woven geotextiles under carriageways, side-drains, and medians are quietly winning the long game. What should we do differently? 📌 Design: Classify soils honestly. Decide where separation vs. filtration is non-negotiable—under base, at drains, behind retaining structures. 📌 Procurement: Insist on tested properties—mass per unit area, grab tensile, CBR puncture, permittivity, and characteristic opening size. Don’t buy by GSM alone. 📌 Execution: Maintain overlaps, protect during placement, avoid wrinkles, place aggregates without tearing, and document with photo logs. 📌 Audit: Random sample rolls on-site, verify mill certificates, and record near-misses like shoulder settlement or drain clogging; fix top 3 causes monthly. Policy nudge: Let’s embed geotextile checkpoints into DPR reviews and BoQ templates, and make site audits for sub-surface layers as routine as cube tests. MoRTH/IRC already give the playbook—our job is to apply it with discipline. Safer roads are a shared responsibility. 💡 I’ll drop a simple visual in comments: “with vs. without separation” showing fines migration and drainage paths. This month, audit two active packages for geotextile use at shoulders and side-drains, retrofit where missing, and publish a one-page remediation plan. If you run fleets, pilot geotextiles in your depot yards to stop rutting and slips after rain. Progress starts under our feet—literally. @NHAI @Civil Engineering Expert @CSR Partner #RoadSafety #Infrastructure #NHAI #MoRTH #IRC #Highways #Geotextiles #Pavements #CivilEngineering #India #Sustainability #CSR

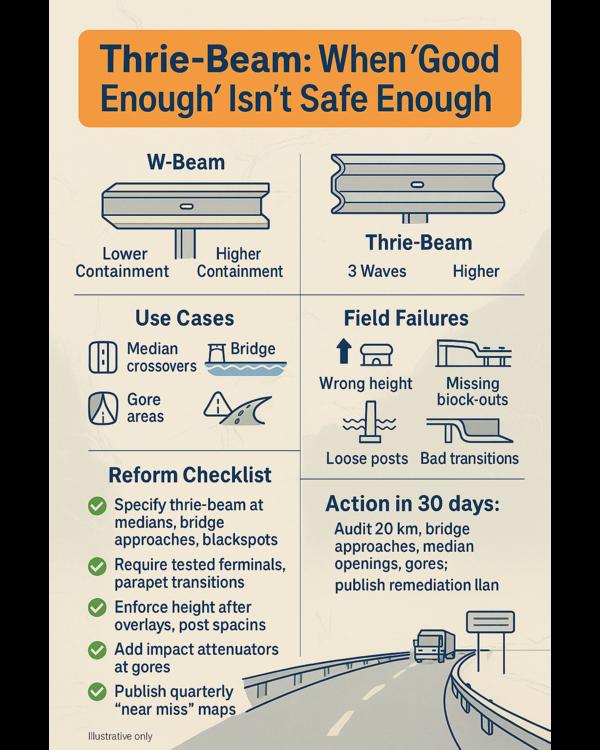

Thrie-Beam: When “Good Enough” Isn’t Safe Enough On every audit drive, the pattern repeats across Mumbai–Pune, Delhi–Jaipur, and Pune–Satara: spotless asphalt… and then a risky gap at bridges, medians, and curves. That’s where Thrie-Beam matters. Wider face. Higher containment. Smoother redirection. It’s the quiet upgrade that turns a preventable tragedy into a survivable incident. Think of Thrie-Beam as W-Beam’s stronger sibling—a three-wave barrier that holds better against heavy vehicles and awkward impact angles. Where? Median crossovers on high-speed corridors, bridge approaches and parapet transitions, gore areas at interchanges, and embankments with steep slopes. The difference is not cosmetic; it’s kinetic. When a truck drifts, the geometry decides whether forces are absorbed and redirected—or a vehicle vaults into oncoming traffic. What breaks in the field is not just the metal; it’s the system. Wrong height after overlays. Missing block-outs. Loose posts. “Buried” ends instead of crashworthy terminals. Abrupt jumps from parapet to W-Beam without a proper transition. We can fix this with discipline, not drama. 📌 Quick reform checklist: ✅ Specify Thrie-Beam at medians with heavy HMV share, bridge approaches, and blackspot clusters. ✅ Demand tested terminals and transitions—to parapets, to W-Beam, to rigid barriers—no improvisation. ✅ Enforce as-built heights after each overlay; post-spacing and block-outs are non-negotiable. ✅ Add impact attenuators at gores/interchanges where speeds are high and deflection room is low. ✅ Publish quarterly “near-miss” heat maps; fix the top three causes before the next quarter. CSR teams can underwrite upgrades on identified blackspots, fund attenuators at ramps, or adopt two school-zone frontages where Thrie-Beam + calming + signage can save young lives. EPCs and PIUs can script this into BOQs today; fleet leaders can push concessionaires to close risky gaps tomorrow. Progress is a series of precise decisions. Safer roads are a shared responsibility. 💡 I’ll drop a simple W-Beam vs Thrie-Beam comparison visual (use cases, deflection ranges, and transitions) in the comments for quick reference. 🚧 Action for this month: pick 20 km of your corridor, audit every bridge approach, median opening, and gore, and publish a 30-day remediation plan. Then do it again next quarter. @NHAI @Civil Engineering Expert @CSR Partner #RoadSafety #Infrastructure #Highways #CrashBarriers #NHAI #PublicPolicy #Engineering #India #Transport #UrbanDevelopment #FleetSafety #CSR

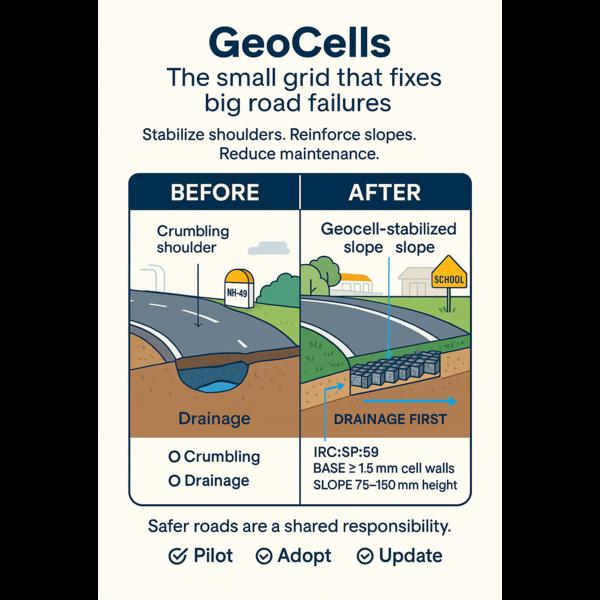

GeoCells: the small grid that fixes big road failures Erosion doesn’t trend on Twitter, but it kills silently. When shoulders crumble or embankments slip, a small swerve becomes a tragedy. India lost 1, 72, 890 lives to road crashes in 2023—and 67% of accidents happened on straight roads, often in open areas where weak edges and poor drainage magnify risk. ([Ministry of Road Transport and Highways][1]) Here’s the reformist fix hiding in plain sight: geocells—those honeycomb grids that confine soil, stiffen layers, and keep slopes where they belong. The Indian Roads Congress already tells us how to use them. For base/subbase reinforcement, IRC:SP:59 recommends a minimum 1.5 mm cell-wall thickness; for slopes, geocell panels 75–150 mm high, properly pinned and joined, act like a flexible armor that resists slippage and invites vegetation. Translation: stronger edges, fewer washouts, safer recoveries. ([Law Resource][2]) This isn’t theory. NHAI corridors have deployed geocells—from embankment protection on NH-15 to stabilization along the Delhi–Bahadurgarh system—because the method works with local infill, speeds construction, and reduces maintenance cycles. ([STRATA GLOBAL][3]) Policy already nudges us in this direction. MoRTH’s 2018 circular urges all agencies to adopt geosynthetics per IRC codes, budget for them in DPRs, and report usage—so “why aren’t we doing this at scale?” is the only honest question.& #x20; 📌 What changes outcomes on ground? — Use geocells where risk concentrates: eroding shoulders near bus bays, culvert approaches, and school frontages. — Specify to code, not catalog: IRC:SP:59 compliance, ≥1.5 mm walls for load-bearing, QA on seams and ESCR. — Design for drainage first, reinforcement second; confinement cannot cure ponding. ([Law Resource][2]) 💡 Practical, near-term actions (pick one this quarter): ✅ Pilot a 2 km geocell-reinforced shoulder on a high-speed straight with recurrent edge failures; publish before-after rutting and repair data. ✅ Adopt two school zones: stabilize embankments and side slopes with geocells plus signage and calming. ✅ Update bid documents: include IRC:SP:59 line items and site QA checks; photograph and log every panel, pin, and joint. Safer roads are a shared responsibility. If your team maintains highways in Mumbai, Delhi, Bengaluru, or Pune, you don’t need another workshop—you need a site, a spec, and a supervisor. In comments, I’ll add a simple visual comparing a fragile shoulder vs. a geocell-stabilized shoulder for your next toolbox talk. @NHAI @Industry Leader @CSR Partner #RoadSafety #Geocells #Geosynthetics #NHAI #Highways #ErosionControl #Pavements #Infrastructure #India #CSR #Construction #PublicPolicy

# Metal Beam Crash Barriers: India’s most affordable life-saving tech 🚧 172, 890 Indians died on our roads in 2023. Over half of those deaths happened in “open areas” with no activity nearby, and two-thirds of crashes were on straight roads—classic run-off and median-crossover scenarios that good barriers are designed to tame. ([Ministry of Road Transport & Highways][1]) Here’s the uncomfortable truth: a W-beam/Thrie-beam costs little compared to a life, yet too many corridors still have gaps, wrong heights, dented rails, or—worst—unprotected ends. IRC:119:2015 is clear: if a barrier end sits inside the clear zone, it needs a **crash-worthy end treatment**. No “fish-tail” shortcuts. ([Law Resource][2]) Policy already backs you. MoRTH’s 01.01.2020 circular made it mandatory that **semi-rigid metal barriers be crash-tested** road-restraint systems, meeting **EN 1317 Part-2** (or MASH) before erection. Translation: use tested systems, installed as per drawings—no jugaad. ([Ministry of Road Transport & Highways][3]) Micro-story from sites across Mumbai–Pune, Delhi–Jaipur, and Pune–Satara: the three things that keep showing up are **missing terminals, sloppy transitions, and poor maintenance**. One heavy hit, bolts shear, posts lean, and the next family pays. We don’t need a miracle; we need discipline. What to do this month—practical, checkable, non-negotiable: ✅ **Audit barrier coverage** on all active packages: medians, bridge approaches, curves, culvert headwalls. Mark every breach >12 m for immediate closure. (Use IRC:119 warrants.) ([Law Resource][2]) ✅ **Verify certificates**: only EN 1317/MASH-compliant systems; keep crash-test reports on file; reject untested “look-alikes.” ([Ministry of Road Transport & Highways][3]) ✅ **Fix the ends**: install crash-worthy terminals and proper transitions to RCC/parapets—no raw cut-offs. ([Law Resource][2]) ✅ **Maintain**: monthly patrols to re-tension, realign, and replace posts/rails after impacts; log and close within 15 days. ([Law Resource][2]) For fleet owners and CSR heads, pair barriers with a safety triad: **enforcement, visibility, training**. Fund transition retrofits at blackspots; adopt 2 school-zone fronts for calming/signage; run quarterly driver refreshers with spot checks. Safer roads are a shared responsibility. 💡 Visual in comments: a one-page “Barrier Readiness Checklist” (EN 1317 compliance • terminal inventory • median-crossover risk map) for your corridor team. 📌 **CTA:** This month, publish a corridor-wise barrier & terminal audit (Mumbai–Pune, Delhi–Jaipur, Kolkata–Durgapur, Bengaluru PRR). Close top 10 defects per package and share before/after photos with your PIU/PMC. @NHAI @Industry Leader @CSR Partner #RoadSafety #Highways #NHAI #CrashBarriers #MoRTH #IRC119 #EN1317 #VisionZero #Infrastructure #Engineering #PublicPolicy #India

A W-beam crash barrier, also known as a guardrail or safety barrier, is a type of protective barrier used along roads and highways to minimize the damage and injuries caused by vehicle collisions. Mr. Hitesh Lunia, 9830777188. omwireproducts@gmail.com/ hitesh.lunia@metalbeambarriers.com #omengineringworks Website : https://www.omwireproducts.com/ http://www.concertinarazorwire.net/ #WBeamCrashBarrier #hitesh.lunia #BniKolkata #bnititankolkata #BNIindia

Concertina wire, also known as razor wire or barbed tape, is a type of fencing material that consists of sharp-edged metal strips or wires intertwined in a coil-like formation. It is commonly used for security purposes and offers several advantages: Mr. Hitesh Lunia, 9830777188. omwireproducts@gmail.com/ hitesh.lunia@metalbeambarriers.com #omengineringworks Website : https://www.omwireproducts.com/ http://www.concertinarazorwire.net #ConcertinaWire #BarbedWire #SecurityFencing #PerimeterProtection #WireObstacles #HighSecurity #SafetyBarrier #BorderSecurity #MilitaryDefense #WireFencing #SecurityMeasures #TacticalSecurity #RestrictedArea #SafetyandSecurity #WireEntanglements #SecuritySolutions #SafetyPerimeter #DefenseSystems #WireConfinement #SecureBoundaries